Dry hire or wet hire? Understanding the difference between the two is essential, not just to control project costs, but also to manage risk, meet safety standards, and ensure operational efficiency.

This guide breaks down both types of crane hire in clear terms, outlining their advantages, disadvantages, and when to use each, whether you’re a site manager, contractor, or procurement officer.

The Australian crane hire market reflects strong demand for both dry and wet hire models. According to IBISWorld, Machinery and Scaffolding Rental Industry revenue is expected to climb $11.8 billion in 2024-25, highlighting its major role in infrastructure and building projects. Cranes and access equipment and Earthmoving and other heavy construction equipment are part of the Machinery and Scaffolding Rental industry in Australia.

What is Dry Hire in Crane Rental?

Dry hire refers to the rental of a crane without an operator, meaning only the equipment is supplied by the crane hire company. It’s the responsibility of the client, typically a builder, contractor, or project manager to provide a licensed crane operator and, in many cases, also a certified rigger and dogmen, depending on the nature of the lifts involved.

This hire model is especially popular among construction firms, civil contractors, and infrastructure project teams who already have in-house resources trained in crane operations. These teams are familiar with local safety regulations, lift planning, and site coordination, allowing them to integrate the crane seamlessly into their workflow. For such clients, dry hire offers not just cost savings, but also the benefit of continuity using personnel they trust and who understand the unique requirements of their project or organization

4 Advantages of Dry Hire

- Cost-Effective for Experienced Teams:

Without the added cost of hiring an operator, dry hire is often cheaper. It gives clients more control over project budgets. As of 2025, hiring a 20-tonne Franna crane in Australia typically costs between $185 and $215 per hour for dry hire, and $210 to $260 per hour for wet hire, depending on factors such as location, duration, and specific project requirements. These cost differences make dry hire an attractive choice for experienced contractors who already have licensed personnel on hand.

- Operational Flexibility:

Contractors can schedule shifts, lifts, and transport at their convenience, using internal resources to match project timelines.

- Familiarity and Trust:

Using your own team ensures you’re working with personnel who understand your processes, safety protocols, and jobsite expectations.

- Wider Use Across Projects:

Many construction firms dry hire multiple cranes for simultaneous use, particularly on large-scale jobs where staffing and coordination are already in place.

3 Disadvantages of Dry Hire

- Operator Certification Required:

You must ensure your crane operator holds a valid high-risk work license and complies with local lifting regulations (e.g., WorkSafe in Australia).

- Increased Liability and Risk:

The hiring party assumes full responsibility for the crane’s safe use. If something goes wrong, insurance claims, damages, or site delays fall on your shoulders.

- No Support from the Rental Provider:

With dry hire, the crane hire company typically won’t assist with lift planning, site inspections, or operational oversight.

What is Wet Hire in Crane Rental?

Wet hire includes not only the crane but also a certified operator provided by the rental company. Depending on the lift requirements, it may also cover a rigger, dogmen, or full lift crew. This type of hire is common on high-risk, technically complex, or time-sensitive projects, where expert handling is critical to safety and efficiency.

Wet hire is ideal when the client doesn’t have internal personnel licensed to operate cranes or prefers to transfer operational responsibility to professionals. The rental provider handles everything from pre-start inspections and lift planning to safety compliance and insurance coverage. This significantly reduces the hiring party’s liability and ensures all legal and regulatory standards are met. Wet hire offers peace of mind, especially for public, civil, or high-value construction works.

4 Advantages of Wet Hire

- Reduced Risk and Liability:

The crane hire company is responsible for the operation, licensing, and insurance of the operator. This significantly reduces the client’s exposure to legal or safety issues.

- Expertise and Experience:

Operators from established crane companies are highly trained, familiar with a range of crane models, and capable of handling complicated lifts with precision.

- Simplified Compliance:

The crane company ensures all safety checks, pre-start inspections, and risk assessments are completed, which helps meet regulatory requirements.

Wet hire also provides a critical safety advantage. As of 2023, machinery operators and driver – which include crane operators – accounted for 37% of all worker fatalities in Australia, totaling 73 deaths. This group also had the highest fatality rate among all occupations, at 8.3 fatalities per 100,000 workers, nearly six times the national average of 1.4 per 100,000 workers. Many of these incidents result from operator error or inadequate training. Hiring a crane with a certified operator significantly reduces these risks and ensures compliance with licensing and insurance standards.

- Time-Saving:

You don’t have to manage staff availability, training, or credential checks, everything is handled by the provider.

3 Disadvantages of Wet Hire

- Higher Costs:

Wet hire is generally more expensive due to labor, insurance, and associated overheads.

- Less Control:

You rely on an external team for equipment operation. This may be a challenge if your project requires strict adherence to internal protocols or scheduling.

- Availability Constraints:

Wet hire cranes are sometimes booked far in advance, especially during peak construction seasons, reducing flexibility for last-minute jobs.

How to Choose Between Dry Hire and Wet Hire

Selecting between dry hire and wet hire depends on several key project and organizational factors. The right choice isn’t just about cost, it’s about balancing risk, capability, and compliance with your project’s specific demands. Here’s how to make an informed decision:

1. Assess Internal Capability

Do you have a licensed crane operator, qualified riggers, and site supervisors familiar with lift plans and safety procedures?

- If yes, dry hire may suit you, offering greater cost control and operational autonomy.

- If no, wet hire ensures your lifts are conducted by experienced professionals with the right credentials.

2. Consider Project Complexity

Is your lift straightforward, repetitive, or located in a controlled environment? Or is it complex, involving high loads, confined spaces, or variable site conditions?

- Dry hire works well for standard lifts where variables are minimal.

- Wet hire is better for intricate lifts needing expert rigging, spotters, and operator judgement.

3. Evaluate Risk and Liability

Who will be liable if something goes wrong , you or the rental company?

- With dry hire, the client is typically responsible for operator conduct, onsite incidents, and insurance compliance.

- Wet hire shifts much of this liability to the rental provider, making it the safer option in high-exposure environments. In fact, contractors using dry hire must carry the full legal and operational risk. In one Queensland case, a labourer was fined $10,000 for operating a crane without a valid license – a risk that could easily be avoided with wet hire. Hiring an insured operator through a crane company shifts much of this liability away from the project team.

4. Budget and Cost Analysis

Dry hire is often cheaper on paper, but hidden costs, such as insurance, downtime from inexperienced operators, or penalties for safety non-compliance, can add up.

- Use dry hire if you’re confident your internal resources will keep operations efficient and safe.

- Use wet hire if avoiding unexpected costs or project delays is your top priority.

5. Time Constraints and Scheduling

Can your team manage crane operations within a tight timeline or adjust to changing lift needs on short notice?

- Wet hire operators are trained for quick deployment and complex logistics.

- Dry hire may require longer coordination unless your crew is always onsite and available.

6. Regulatory Requirements

Some government and Tier 1 infrastructure projects mandate that all crane operations be carried out under wet hire to ensure licensed, insured operators are handling high-risk lifts. Check your project tender or contract terms to confirm what’s allowed.

7. Long-Term vs Short-Term Use

- Dry hire is often more economical for long-term jobs where in-house teams are already deployed.

- Wet hire is ideal for short-term, high-stakes, or one-off lifts, where efficiency and risk management are critical.

Regulatory and Safety Conditions

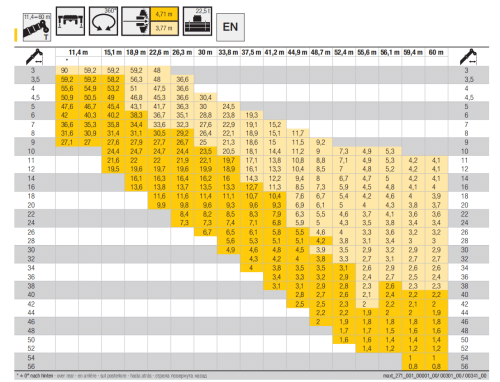

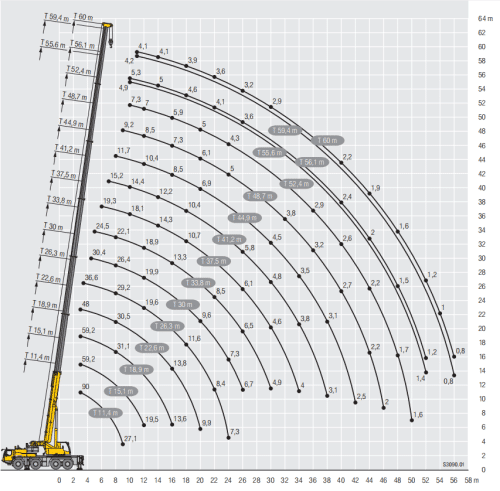

Crane operation is heavily regulated in most countries. In Australia, operators must hold the appropriate High-Risk Work Licence (HRWL) for the specific crane class. Projects must comply with the Work Health and Safety (WHS) Act and Codes of Practice relating to lifting operations. Equally important is the ability to read and interpret a crane load chart accurately, as it ensures each lift is performed within the crane’s rated capacity and prevents overloading.

In wet hire, the crane provider assumes responsibility for:

- Operator qualifications and compliance

- Maintenance logs and equipment inspections

- Load chart documentation

- SWMS (Safe Work Method Statements)

In dry hire, all the above becomes the client’s responsibility. That’s why thorough safety planning and risk assessment are vital if you’re opting for dry hire.

Which Option is Right for You?

Both dry hire and wet hire have their place in modern crane operations. If your team has the certifications, safety systems, and project scale to manage dry hire effectively, it can save money and offer greater flexibility. On the other hand, wet hire offers peace of mind, especially for complex or safety-critical jobs.

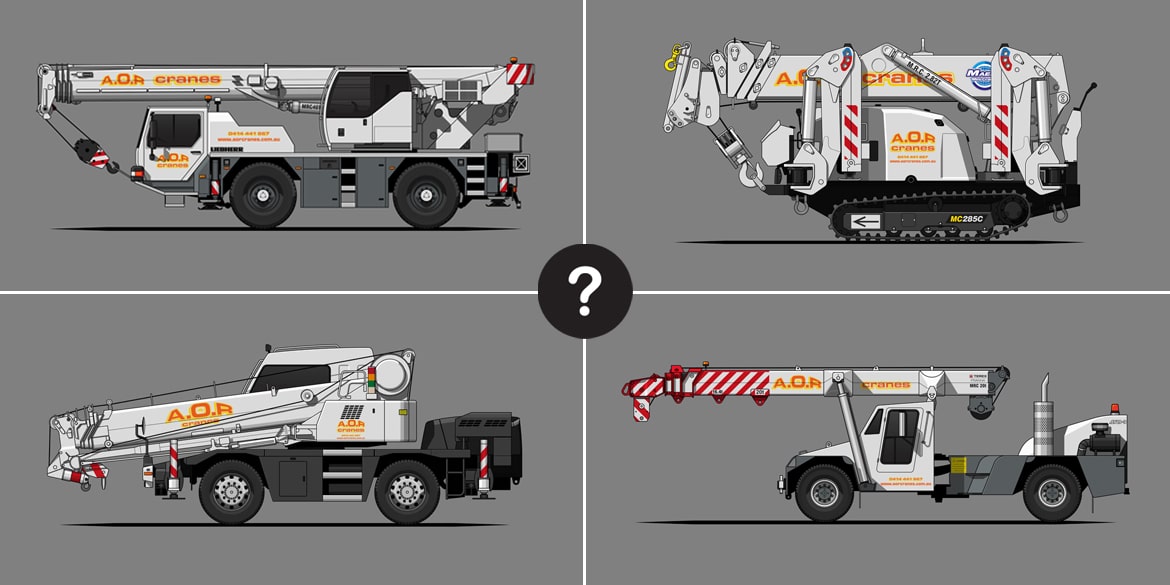

At AOR Cranes, we offer both dry and wet hire crane services with a fleet that includes mobile cranes, franna cranes, slewing cranes, and all-terrain units, all maintained to the highest safety standards. Whether you need total project support or just the right crane at the right time, we’re ready to deliver.

AOR Cranes is dedicated to delivering top-notch crane hire services with safety, reliability, and expertise at the core. With over 30 years of experience, we handle every project with care and expertise to meet your needs.