When a rooftop HVAC crane lift goes to plan, the crane sets up smoothly, traffic keeps moving, tenants stay comfortable, and the new system drops onto the plant platform with zero drama. That positive outcome starts with solid information and a clear lift plan. Weights, dimensions, roof layout, access, traffic control and the right choice of crane all shape how safe and successful the project goes on the day.

HVAC contractors, builders and facility managers who line these details up early with their crane hire partner get shorter crane hire windows, fewer site issues and a smoother changeover for everyone in the building. The more you know about the factors that go into planning a HVAC lift, the more successful the outcome.

Please Note: Always check the current NSW laws, the Work Near Overhead Power Lines Code of Practice and the electricity supply authority’s written advice for your specific site.

Why Careful Planning Matters For Rooftop HVAC Lifts

Safety Above Live Workspaces

A rooftop plant lift puts heavy HVAC units over offices, retail spaces and public areas. Poor planning increases the chance of near misses, damaged equipment or debris in public zones. Clear lift paths and well defined exclusion zones keep the load under control from street to plant platform. The goal is always to protect people on the ground and the crews on the roof.

Time, Cost And Tenant Impact

Crane hire is charged by the hours. Vague details lead to extra setup time, late changes to rigging and longer traffic control shifts. When everything is confirmed early, the crane turns up sized correctly and sets up faster. That keeps crane hours tighter, reduces disruption to tenants and helps mechanical teams complete the changeover in a single clean window.

Step 1: Gather The Right Project Details

Weights And Dimensions

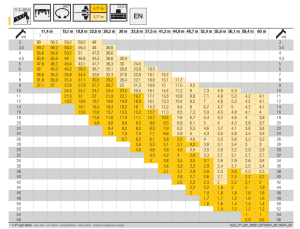

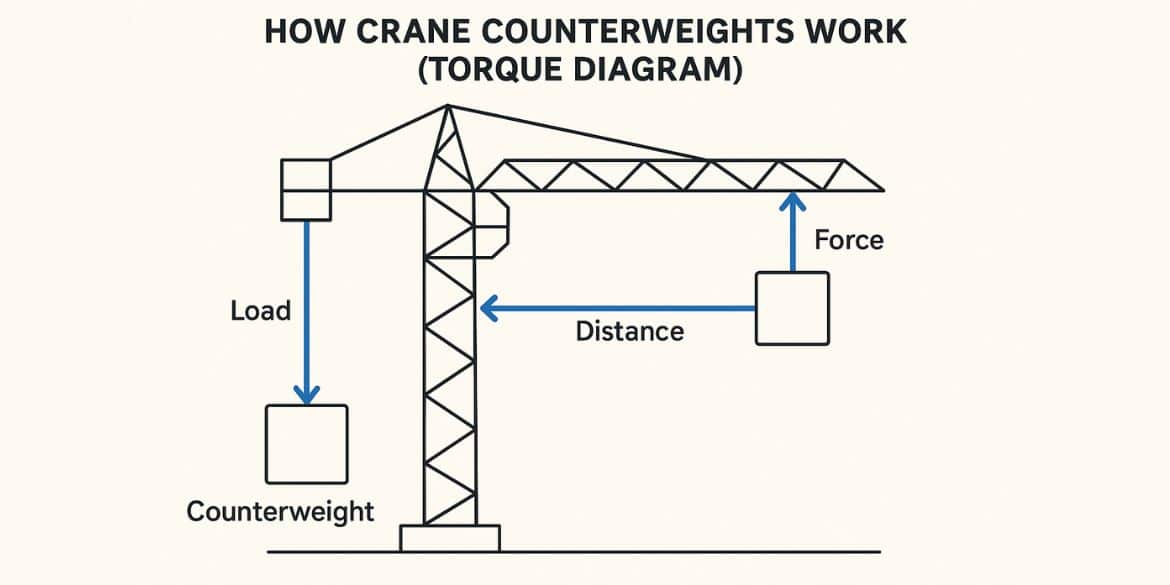

Start with the numbers for every rooftop HVAC crane lift. Confirm unit weight, overall dimensions and, if available, centre of gravity from the manufacturer. Include frames, skids and any duct or plant sections that travel on the hook. Clear figures let the crane hire team check capacity at the working radius and match the lift to a suitable city crane or all terrain crane.

Roof Layout And Plant Platform

Now it’s time to map the roof. Mark plant platforms, parapets, balustrades and services that sit near the lift path. Take photos from several angles and share any roof or structural drawings you can access. The crane crew can then see how the load will travel and where riggers can move safely around the plant.

Step 2: Choose The Right Crane For The Lift

City Cranes In Sydney

City cranes suit tight commercial streets and narrow loading bays. They can be set up close to the facade and still deliver useful reach for rooftop HVAC units on low to mid-rise buildings. For many plant lift jobs in Sydney, a well planned city crane setup keeps traffic impacts smaller and makes the lift feel more controlled.

When To Use An All Terrain Crane

All terrain cranes step in when the plant is heavier, the roof is higher or the radius grows. They carry stronger load charts and offer more boom length. This suits large chillers, grouped plant replacement and taller commercial buildings where extra reach and capacity give a bigger safety margin.

Step 3: Plan Rigging, Lift Points And Load Stability

Confirm Safe Lift Points

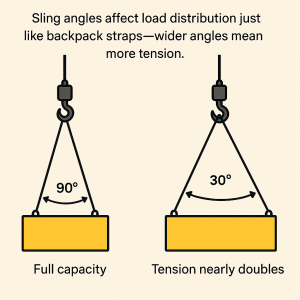

Check manufacturer drawings for rated lifting points or seek an engineer’s sign off. Mark those points clearly before crane day so everyone knows where slings attach. A short toolbox talk on the roof helps the crew agree on orientation and how the unit should sit on the hook.

Protect The Unit During The Lift

Select spreader bars, lifting beams, soft slings and shackles that protect coils, casings and finishes. Aim to keep the HVAC unit level as it rises, slews and lands on the plant frame. Riggers and dogmen control the hook and guide the load through tight spots, especially near parapets or glass.

Step 4: Plan Access, Crane Setup And Traffic Management

Choose A Safe Setup Location

Look at ground conditions around the building. Confirm bearing capacity, check for basements or underground services and note any weak pavements. From there, pick a crane position that gives a clean lift path and keeps the radius within the crane chart. Plan staging areas for new units, old plant and waste bins so nothing clutters the setup zone.

Manage Traffic, Pedestrians And Permits

If the crane or load sits over a road or footpath, you’ll need a traffic management plan. Factor in lane closures, traffic controllers, pedestrian detours and barriers under the lift path. Council permits and notifications can take time. Line these up early with support from your crane hire partner.

Step 5: Sequence The Lift To Reduce HVAC Downtime

Schedule The Plant Lift Window

Pick a lift window that works for the building. Early mornings, evenings or weekends often suit commercial tenants and reduce traffic pressure around the site. Keep an eye on local noise rules and allow a buffer for weather so the crane isn’t rushed.

Coordinate Trades And Changeover

Do as much assembly as you can at ground level. Pre-build frames, skids and small sections so the crane places complete units on the roof. Sequence the work so the old systems come down first. New HVAC units will land straight after, then ancillary items follow. Electrical and mechanical teams should be ready to reconnect once the last lift is done to keep downtime short.

Step 6: Run A Safe Crane Day On Site

Pre-Start, Roles And Communication

Hold a pre-start before the first lift. Bring together the crane operator, riggers, HVAC contractor, builder, facility manager and traffic controllers. Confirm the lift plan, exclusion zones, radio channels and signals, wind limits and emergency procedures. Clear roles stop confusion once the crane starts moving.

Documentation And Compliance

Keep paperwork close at hand. That includes SWMS, lift plans, crane logbooks, Crane Safe Certification and inspection records for rigging. Site-specific inductions, permits and access conditions for the commercial building should also be closed out before the crane sets up. A tidy file keeps auditors happy and shows everyone on site that the rooftop HVAC crane lift is under control.

Rooftop HVAC Crane Lift Planning Checklist

- HVAC unit weight confirmed from manufacturer data

- Overall dimensions and centre of gravity noted

- Frames, skids and loose items on the hook listed

- Roof layout mapped with photos and drawings

- Plant platform, parapets and nearby services marked

- City crane or all terrain crane selected with real radius checks

- Lift points confirmed by manufacturer or engineer

- Lift points marked on the unit before crane day

- Spreader bars, lifting beams and slings selected

- Crane setup location checked for ground capacity and services

- Staging areas for new and old plant agreed

- Traffic management plan prepared with lane and footpath controls

- Council permits lodged where public roads or paths are affected

- Lift sequence agreed for removal and installation

- Electrical and mechanical teams booked to match the crane window

- Pre-start meeting planned with all key people

- SWMS, lift plan, logbooks and certifications ready on site

Plan Your Next Rooftop HVAC Lift With AOR Cranes

A well planned rooftop HVAC crane lift is the best way to ensure a successful operation. The crane sets up cleanly, traffic keeps flowing where it needs to, and the new unit touches down on the plant frame without drama. That outcome needs a crane partner that knows Sydney’s streets, understands commercial buildings, and treats safety as non-negotiable.

AOR Cranes brings more than 30 years of lift planning and execution across Sydney, including complex work for major utilities and live sites, with crews who are used to tight access and sensitive environments.

Their team can help lock in the right city crane or all terrain crane, prepare lift studies and SWMS, and coordinate traffic control so each plant lift runs to plan. If you’re lining up a rooftop HVAC or plant lift in Sydney, share your unit data, drawings and photos early so AOR can build a safe, efficient lift plan around your window of downtime.

If you need crane hire for a rooftop HVAC or plant lift in Sydney, get in touch with AOR Cranes or call 02 9024 9425.

Rooftop HVAC Crane Lift FAQs

How Early Should I Book A Crane For A Rooftop HVAC Lift?

Aim to lock in crane hire as soon as you know the plant changeover date. Two to four weeks gives time for lift planning, traffic management and any council permits.

What Information Does A Crane Hire Company Need For A Rooftop HVAC Lift?

You’ll need unit weight, dimensions, any extra items on the hook, roof layout and clear photos. Drawings of the plant platform and street access help the crane team pick the right city crane or all terrain crane.

Do I Need A Lift Plan For A Rooftop HVAC Crane Lift?

Yes. A lift plan sets out crane size, setup location, radius, rigging, lift path and exclusion zones. It keeps the site safe and helps everyone work to the same sequence.

Who Organises Traffic Control And Permits In Sydney?

Traffic control and permits are usually coordinated between the builder, HVAC contractor and crane hire company. Many clients ask the crane team to help arrange traffic management plans, controllers and council approvals as part of the plant lift package.

How Does Weather Affect A Rooftop HVAC Lift?

High wind, lightning and heavy rain can stop lifts. Your crane hire partner will work to wind limits on the crane chart and may pause or reschedule if conditions change on the day.

AOR Cranes is dedicated to delivering top-notch crane hire services with safety, reliability, and expertise at the core. With over 30 years of experience, we handle every project with care and expertise to meet your needs.