Crane Lift Plan: Key Elements and Mistakes to Avoid

In high-risk environments like construction and infrastructure development, lifting operations involving cranes demand meticulous preparation. A single miscalculation in crane setup, load capacity, or environmental conditions can lead to catastrophic consequences. According to Safe Work Australia, crane-related incidents accounted for over 240 serious injury claims in the construction industry in a recent five-year period. To mitigate such risks, a crane lift plan serves as the operational blueprint that ensures each lift is executed safely, efficiently, and in compliance with national regulations.

What is a Crane Lift Plan?

A crane lift plan is a comprehensive strategy that outlines how a crane will be used to safely lift, move, and place a load. It serves as a safety and coordination document that considers all the variables involved in the lift, including site conditions, weather, equipment, personnel, and load characteristics.

According to Australian standards, particularly AS 2550.5 and Work Health and Safety Regulation 2011, lift plans are mandatory for high-risk operations. These plans should not be treated as one-size-fits-all templates. Instead, they must be tailored to the site and the complexity of the lift.

Scenarios requiring a crane lift plan include:

- Lifts exceeding 75% of rated crane capacity.

- Lifts performed near active traffic, overhead powerlines, or public zones.

- Tandem or multiple crane lifts.

- Lifts involving personnel hoisting or non-routine load configurations.

Creating a lift plan in these scenarios ensures that everyone on site, from supervisors to riggers, is aware of their responsibilities, the sequence of operations, and emergency protocols.

8 Key Elements of a Crane Lift Plan

A well-structured crane lift plan isn’t just a formality; it’s a proactive risk management tool. Each component of the plan plays a distinct role in reducing hazards, streamlining communication, and ensuring regulatory compliance. Below is a detailed breakdown of what must be included and why each element matters.

1. Load Characteristics

Before any crane even starts its engine, you need a full understanding of the load to be lifted. That means:

- Accurate weight calculation: Use certified documentation or load cells if unknown. Misjudging weight can lead to boom failure or tipping.

- Load geometry: Irregular shapes require customized rigging solutions.

- Center of gravity (CoG): If the CoG isn’t centered beneath the hook, the load may swing, rotate, or shift mid-air.

Example: Lifting a steel tank that’s wider at the base demands precise identification of the CoG to avoid tilting.

Pre-Lift Load Characteristics Checklist

- Use this if you’re hiring a crane or preparing a lift plan.

- Is the total load weight known and verified?

- Have load dimensions (L × W × H) been measured and documented?

- Has the center of gravity been identified or estimated?

- Is the shape regular or does it require special rigging?

- Are lift points clearly marked and structurally sound?

- Is the load rigid, flexible, or likely to deform in the air?

- Does the load require surface protection (e.g., padding, spreaders)?

- Have you shared drawings or photos of the load with your crane provider?

2. Crane Specifications

Not all cranes are created equal, and using the wrong crane type for a lift can be disastrous.

- Crane type: Mobile, tower, or crawler? Each has different mobility, capacity, and setup needs.

- Load chart reference: Always consult the crane’s load chart for boom length and radius combinations.

- Setup parameters: Include outrigger placement, counterweights, slewing limitations, and tail swing clearance.

Quick Guide: Choosing the Right Crane for Your Lift

Selecting the wrong crane can delay your project or compromise safety. Here’s a simplified breakdown to help you match crane type to your site needs:

- Mobile Slew Cranes

Fast to set up, road-legal, and ideal for general construction lifts with good access.

Best for: Rooftop HVAC, steel beams. - Crawler Cranes

Great for heavy lifts on soft or uneven ground. Requires more setup space.

Best for: Bridge work, remote infrastructure. - Tower Cranes

Fixed to site, perfect for vertical lifting on high-rise projects.

Best for: Apartments, commercial buildings. - Rough Terrain Cranes

4WD and stabilizers make them ideal for off-road, uneven job sites.

Best for: Wind farms, pipeline work. - Pick and Carry (Franna)

Compact, mobile, great for quick shifts of light loads.

Best for: Onsite equipment moves.

Read more for a detailed guide on selecting right crane for every job .

3. Rigging Configuration

This is often where plans go wrong. Inadequate rigging is a leading cause of dropped loads.

- Rigging gear selection: Ensure WLL (Working Load Limit) is suitable. Slings, shackles, hooks, and spreader bars must be matched to the load.

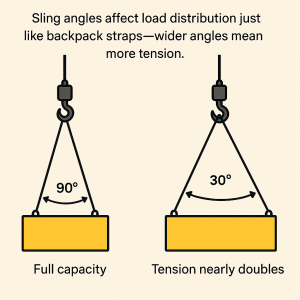

- Sling angles: Sharper angles increase tension on slings. Calculations must factor this in.

- Inspection logs: All rigging gear should be inspected and tagged before the lift.

As shown in the image below, sling angles significantly affect load distribution. Therefore, selecting the correct angle is crucial for a safe and stable lift.

4. Ground and Environmental Assessment

A crane’s lifting capacity depends on several factors, including weather and ground conditions.

- Soil bearing capacity: Must be verified to prevent sinkage or instability.

- Underground services: Always locate utilities before setup, contact Dial Before You Dig in Australia.

- Weather considerations: Wind speed affects the lifting capacity of cranes with high boom lengths. Lifts should be rescheduled if wind speeds exceed crane-specific limits (typically 36 km/h for mobile cranes). Also consider lightning, heavy rain, or poor visibility.

5. Lifting Path and Movement

It’s not just about going up and down, lateral movement introduces complexity and additional hazards.

- Load path planning: Map the full travel route of the load to avoid contact with obstacles like scaffolding, overhead cables, or nearby structures.

- Crane swing radius: Define and mark the area around the crane’s rotation zone to prevent personnel from entering dangerous zones during operation.

- Emergency drop zones: Pre-designate safe areas where the load can be lowered quickly in case of equipment failure or sudden environmental hazards.

6. Personnel and Supervision

People are the most critical part of any lift.

- Named personnel: Every lift plan must list the crane operator, dogman, rigger, lift supervisor, and spotters.

- Competency verification: All must hold valid High Risk Work (HRW) licences per Safe Work Australia.

- Toolbox talks: Conduct a pre-lift briefing to review responsibilities and site hazards.

7. Communication Plan

Clear, fail-safe communication is vital, especially when visibility is limited or when lifting in noisy environments.

- Primary system: Most sites use two-way radios with a designated channel.

- Secondary system: Hand signals, standardized under AS 2550.1, serve as backup.

- Spotters and signalers: Should be clearly identified in PPE and remain in direct line-of-sight or radio contact.

8. Emergency Protocols

Things go wrong, even with perfect planning.

- Wind shutdown procedures: Know your crane’s wind limits and stick to them.

- Mechanical failure response: Have trained personnel ready to engage emergency brakes or drop loads safely.

- Evacuation plans: Include routes, assembly points, and contact numbers in the lift plan.

Standard vs. Critical Lifts

Not all lifts are created equal. Some crane operations are straightforward and occur in controlled environments, while others involve complex load dynamics, tight working spaces, or high-consequence environments. This is where understanding the difference between standard and critical lifts becomes essential.

A standard lift typically involves known loads under controlled conditions, using a single crane well within its capacity. These lifts follow routine procedures and generally don’t require engineering review beyond basic compliance checks.

In contrast, a critical lift involves elevated risks, whether it’s lifting close to the crane’s capacity, working over live plants or public spaces, performing tandem crane operations, or involving expensive or irreplaceable loads. Critical lifts require additional scrutiny, including peer-reviewed lift calculations and constant supervision by experienced personnel.

Here’s a side-by-side comparison for clarity:

| Criteria | Standard Lift | Critical Lift |

| Capacity Usage | ≤ 75% of crane rating | ≥ 90% or multi-crane coordination |

| Load Type | Known and simple | Complex, large, sensitive, or unknown loads |

| Risk Environment | Controlled, clear zone | Crowded site, near public or utilities |

| Documentation | Basic lift plan | Full engineered lift plan with supporting calculations |

| Supervision | Lift supervisor recommended | Mandatory full-time lift supervisor with sign-off authority |

Safety and Legal Importance

Lift plans are not just internal guidelines, they are enforceable documents that demonstrate duty of care under Australian law. Failure to implement a crane lift plan that meets WHS regulations can result in fines, project delays, or worse, fatal incidents.

- They also provide an audit trail for:

- Site inspectors and project auditors

- Insurance claims following incidents

- Root cause analysis in case of mechanical failure or human error

A documented lift plan also protects crane operators from liability when procedures are followed correctly. According to WorkSafe NSW, several serious crane accidents could have been prevented if documented lift procedures had been followed.

5 Common Mistakes to Avoid

Some frequently overlooked errors in crane lift planning include:

- No lift plan for routine lifts: Every lift involving non-trivial weights or public risk should be documented.

- Improper rigging assumptions: Using slings that are improperly angled or worn out drastically increases failure probability.

- Missing wind monitoring protocol: Even moderate winds can destabilize long boom lifts.

- Untrained spotters: Spotters must be trained in crane movement and hand signal standards.

- No trial lift or dry run: Testing the lift with a partial load or empty hook can expose issues before the full load is handled.

Final Thoughts

Crane lift planning is about more than compliance, it’s about foresight, collaboration, and accountability. Every successful lift begins long before the crane is on site, with a well-researched, site-specific plan that anticipates the unexpected.

When in doubt, consult a certified lift planner or engage crane hire specialists with engineering capabilities. Proper documentation and preparation today can prevent disaster tomorrow.

For reliable, fully compliant crane lift planning and execution, explore how AOR Cranes supports complex lifting projects across Sydney, NSW.

AOR Cranes is dedicated to delivering top-notch crane hire services with safety, reliability, and expertise at the core. With over 30 years of experience, we handle every project with care and expertise to meet your needs.